- HOME

- l

- Company

- l

- Products

- l

- Business Line

- l

- Contact us

- l

- Sitemap

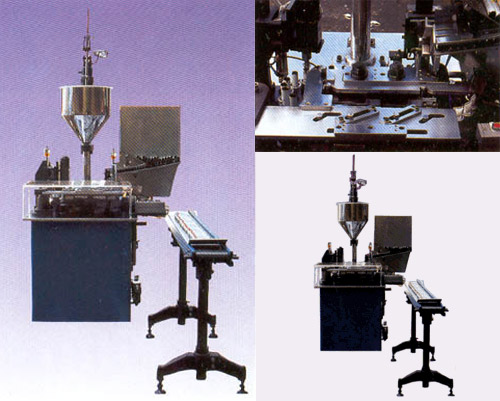

DY-03 Tin, Aluminum Tube Filling Machine

Home > Company > Products List

Specifications

- Application : Pigment, Ointment, Eyebrow bond, Stationery bond, Viscous liquid etc.

- Filling range : 1g-20g

- Filling accuracy : +/- 0.1%

- Tube material : Aluminium tube, Tin tube

- Tube size : Diameter : 8-19mm / Length : 30-85mm

- Capacity : 3300-4000 Tubes/hr

- Voltage : 220V , 380V

- Motor for machine start-up : Speed convertible type (Feeding speed) 3P 0.5kw 60-50/hz

- Delivery : 30 days

- Machine size : W: 710 L:1150 H: 2000 (Unit: mm)

- Seal type :

- Net Weight : Approx' 600kg

- Guarantee : 24 months (After sales service free of charge during guarantee period)

- Filling range : 1g-20g

- Filling accuracy : +/- 0.1%

- Tube material : Aluminium tube, Tin tube

- Tube size : Diameter : 8-19mm / Length : 30-85mm

- Capacity : 3300-4000 Tubes/hr

- Voltage : 220V , 380V

- Motor for machine start-up : Speed convertible type (Feeding speed) 3P 0.5kw 60-50/hz

- Delivery : 30 days

- Machine size : W: 710 L:1150 H: 2000 (Unit: mm)

- Seal type :

- Net Weight : Approx' 600kg

- Guarantee : 24 months (After sales service free of charge during guarantee period)

Product Features

- Our sealing Aluminum Tube Filling Sealing machin is running under low temperature.

So, there is no any result for contents from chemical response.

- To seal tube under low temperature that make tube perfectly round without wrinkled surface.

Round surface look in beau and high quality goods.

- Filling amount is precise.

- Sealing part is shine.

- No tails occurred after Filling and there will be no stain along the tube side.

- Since the sealing is done under cooling condition the contents does not chemically

response and its quality last long time.

- Compatibility is excellent when changing colors.

- Less noisy than other product when operated.

- The Tin,Aluminum tube Filling machine could last more than 15 years.

- With the convenience to clean the Laminate Plastic Tube Filling machine could be used

in rather sanitary way.

- Stainless steel is used around the injection part.

So, there is no any result for contents from chemical response.

- To seal tube under low temperature that make tube perfectly round without wrinkled surface.

Round surface look in beau and high quality goods.

- Filling amount is precise.

- Sealing part is shine.

- No tails occurred after Filling and there will be no stain along the tube side.

- Since the sealing is done under cooling condition the contents does not chemically

response and its quality last long time.

- Compatibility is excellent when changing colors.

- Less noisy than other product when operated.

- The Tin,Aluminum tube Filling machine could last more than 15 years.

- With the convenience to clean the Laminate Plastic Tube Filling machine could be used

in rather sanitary way.

- Stainless steel is used around the injection part.

Technology & Certification

- ISO9001

- EN 46002

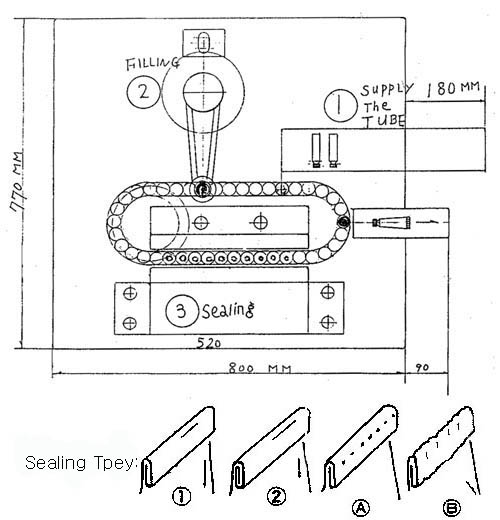

1) Seal method : fold sealing

2) On backside,printing the manufacturering date/month/year by every weekly.

3) We have mounting ligjt censer to print character on middle spot of tube middle spot of tube.

4) Automatically ,the tube move down and up and control.

5) Sealing size : according to the size of tube to seal from 3mm to 5mm.

6) Photocell that could scan the tube print registration mark is being setting.

7) Our machine is controlled the speed by frequency conversion as you want timing .

- The Tube Filling Sealing machine gets high efficiency especially for small amount Filling.

- When inject various colors they can be changed rapidly.

- Hopper, Filling and cleaning the nozzles are very convenient while assemble and disassemble

is somewhat handy compared with other product from elsewhere so that operator can assemble

and disassemble it upon 2 minutes explanation

- EN 46002

1) Seal method : fold sealing

2) On backside,printing the manufacturering date/month/year by every weekly.

3) We have mounting ligjt censer to print character on middle spot of tube middle spot of tube.

4) Automatically ,the tube move down and up and control.

5) Sealing size : according to the size of tube to seal from 3mm to 5mm.

6) Photocell that could scan the tube print registration mark is being setting.

7) Our machine is controlled the speed by frequency conversion as you want timing .

- The Tube Filling Sealing machine gets high efficiency especially for small amount Filling.

- When inject various colors they can be changed rapidly.

- Hopper, Filling and cleaning the nozzles are very convenient while assemble and disassemble

is somewhat handy compared with other product from elsewhere so that operator can assemble

and disassemble it upon 2 minutes explanation

Additional Information

I am as a 1st class technician and master hand specialized in manufacturing Aluminum Tube Filling Sealing Machine and Tube filling Manufacture Machine since 1978.

The Korea has been enjoying high reputation as a winner of international vacational training competition for 13 times including 10 consecutive years winning 1st place. Also we Daeyong as a Tube Filling machine technical expert in Korea are proud of the function of products we are manufacturing. We are sure that you would be satisfied using our Tin, Aluminum Tube Filling Sealing machine we manufacture with our heart. We wish your prosperous business and remain.

Click

Click